Solar Cool Houses in the Desert

{A patent spec prepared and then postponed for the time being.}

Abstract

Solar Cool-houses are like traditional

greenhouses but a significant difference is that they create a cool environment

for plants to thrive in an otherwise harsh (hot and dry) environment. They will have

transparent roofs covered with transparent solar photo voltaic (PV) panels and hot water

heaters. During the day under the sun, the transparent PV panels produce

electric power which can be used to generate chilled water or cool air to keep

the greenhouse environment cool. Locally available non-potable water or sea

water is heated in the water heaters and through desalination process, convert

it to water suitable for plants.

As global population increases, there is a

greater demand for food, water, and energy. Solar photovoltaic (PV) systems are

increasingly used as energy generators. But, such systems occupy large tracts

of land competing for land, which is needed to grow more food. Solar cool houses

can be built on the vast tracts of currently waste lands that are desert like,

fallow, and barren. Thus, such lands in the harsh, hot, and dry desert-like

environments can be converted into flourishing crop lands.

By a proper selection of materials for the

solar cells for the PV panels, the wavelengths of light in solar spectrum that

are utilized for photosynthesis are passed through to the plants in the

cool-house. Thus, one hundred per cent of the energy in the solar radiation

incident on the roof is absorbed by the PV panels, the plants, and the water in

the hot water heaters.

Any excess or deficit of electric energy

generation in a solar cool house complex is exchanged with the electric power

grid. Deserts and arid lands usually have very inferior soils. In such

locations and situations, hydroponics, and pisciculture can thrive in the cool houses.

BACKGROUND

Field

of the Invention:

This

invention relates to solar coolhouses to create a suitable environment to grow

plants in an otherwise harsh hot and dry desert-like environment while

generating electric power with transparent solar photovoltaic (PV) panels on

top of the coolhouse roofs.

The

present invention describes a coolhouse that has transparent solar PV panels

fixed to a structure with a transparent roof to create an environment suitable

to grow plants in the coolhouse. Solar radiation of certain wavelengths is

essential for photosynthesis, a biochemical process through which plants take

advantage of sunlight and generate life sustaining vegetable foods. But the

severity of the solar radiation in a desert is highly detrimental to vegetation.

Another aspect of the present invention is directed towards using a part of the

energy from the solar spectrum to generate electricity through transparent photo

voltaic (PV) panels on the roofs, using another part of the solar radiation to

heat sea water for desalination, and allowing the rest of the solar radiation

spectrum to be used by plants for photosynthesis. This effect is accomplished

by properly shielding the crops from the full impact of direct solar radiation

and by distributing the solar radiation by suitably building coolhouses to allow

plants to thrive. The electric energy generated by the transparent photovoltaic

panels is used to generate clean water needed by the plants from sea water or

hard water by desalination and to run the air conditioning equipment to create

a thriving environment in the coolhouse and any excess or deficit of electric

energy generation is exchanged with the electric power grid.

Deserts

and arid lands usually have very inferior soils. In such locations and

situations, it is proposed to use the coolhouses for hydroponics, and

Pisciculture.

Description

of the Related Art:

As

global population increases, humans depend on every acre of land and every

gallon of fresh water to raise food needed by the billions of people in the

world. Life sustaining food results from agriculture, which critically depends

on land, fresh water, energy, solar radiation, and proper environment.

As

they run out of fertile farm lands, nations have been trying to cultivate new

lands that are dry, arid, fallow, and desert like harsh environments. Constant

efforts are being made to bring new sources of water including desalination of

seawater and reuse of dirty and hard water. New and affordable sources of

energy, where available, are being applied to improve agriculture. Technology

and designs to augment solar radiation in extremely cold as well as hot and dry

climates are being applied in concert with other methods to improve agriculture

and gain better yields.

In

cold climates, greenhouses are built to augment the local environment to extend

the periods when vegetables and fruits can be grown. Greenhouses are also known

as glasshouses, hothouses, or coldframes. These structures are covered with a

transparent layer made of plastic film, rigid plastic, or glass. The cover

permits natural light to enter to allow plant growth but prevents cold air to

enter or warm inside air to exit. The inside temperature is maintained by

heating with an external source as needed. Although most of these efforts are

expensive in terms of initial costs, cultivation of proper vegetables, fruits,

flowers, and other crops results in attractive economic returns.

Desert farming generally relies on irrigation with the Imperial Valley

in California is a good example of successful desert farming. One

problem associated with raising traditional plants in a desert is depletion of

the ground water.

Drip irrigation is one way to reduce the overall water demand especially in

desert areas.

The geography of Israel is not naturally conducive to

agriculture as more than half of the land area is a desert, the climate is

harsh, and the country lacks water resources. With hot daytimes and cold night

times, hothouse technology is used to grow vegetables in that country.

SolarSpring

developed clean-energy water systems in remote areas by using solar

photovoltaic systems to desalinate and treat seawater and non-potable water. Solar

thermal energy is used to heat and evaporate seawater or dirty water and the

water vapor is subsequently cooled to produce clean water by a process called,

solar humidification-dehumidification (HDH) process. The energy required for pumping

the water is powered by solar photovoltaic panels. The creation of fresh water

by the desalination of water using the waste heat from Concentrating Solar

Power (CSP) plants—a welcome bonus in arid regions.

In the interior areas of continents, other water sources, such as, groundwater

with mineral contaminants (e.g. Arsenic), degraded wells, and streams with

mineral contamination, are available but cannot be used directly for

agriculture. Zonnewater BV developed an

optimized solar thermal distillation system. It is intended to produce premium

drinking water as well as water for agricultural applications from different

available sources in tropical and sub-tropical locations.

A pilot plant

built by the Sahara Forest Project (SFP) produced 75 kilograms of vegetables

per square meter in three crops annually, comparable to commercial farms in

Europe, while consuming only sunlight and seawater. SFP designed a special

greenhouse in Qatar. At one end of the greenhouse, salt water is trickled over

a grid-like curtain so that the prevailing wind blows the resulting cool, moist

air over the plants inside. This cooling effect allowed the facility to grow

three crops per year, even in the scorching summer. At the other end of the

greenhouse is a network of pipes with cold seawater running through them. Some

of the moisture in the air condenses on the pipes and is collected, providing a

source of fresh water.

While

traditional methods of agriculture use vast quantities of water, and fertile

soil, hydroponics utilizes several times lower quantities of water and uses no

soil at all. Plants are grown in inert medium or in water itself. Of course, in

either case, liquid nutrients are added to water.

Pisciculture

improves on hydroponics as it allows both fish and crops to grow together. The

plants thrive by using the rejects from fish as supplementary nutrients and the

fish use parts of the plant as food. Pisciculture also uses less water than

traditional agriculture.

With issues of

climate change and greenhouse gases putting pressure on fossil fuel-based

thermal plants, solar photovoltaic energy generation is gaining favor. But,

this trend would take away vast areas of land from agriculture when the PV

plants are situated on ground. There is a hope that there is potential for

growing plants for food and

other uses in the shaded areas under the solar mirrors. It is also possible to

use desalination of sea water to water the plants. But without full enclosures,

hot winds and fierce sand storms will still cause problems for plant

cultivation in the deserts.

Every year, each

square kilometre of desert receives solar energy equivalent to 1.5 million

barrels of oil. Multiplying by the area of deserts worldwide, this is several

hundred times as much energy as the world uses in a year. Hence, there is a

constant effort to utilize solar energy fully and benefit from it.

Figure

1 shows the solar radiation spectrum. Solar radiation spans wavelengths from

250 nanometers to 2,500 nanometers covering the Ultra Violet (UV), Visible, and

Infra-Red (IR) regions. Plants use only some of the light in the 400–700 nm range. Hence, 47% of

the incident solar radiation comprises non-bioavailable photons, which is not useful for photosynthesis of the

plants but is converted to heat under normal circumstances.

Of

the global radiation reaching Earth’s surface as shown in Figure 1, on average,

45% of the incoming solar radiation falls within the range of 389 to 710 nm.

This is the range utilized via photosynthesis by plants. This range is often

defined as photosynthetically active radiation, PAR, and is often denoted by

the range between 400 to 700 nm as shown in Figure 2. It may further be noted

that of the 100% total energy received by the leaf, only 5% is converted into

carbohydrates and later for biomass production. The amount of energy lost by

nonabsorbed wavelengths is thus 60%; this energy is reflected by the plants

into the surrounding atmosphere.

Figure 2 also shows the response of various types of

chlorophyll in plants to light. This examination of the characteristics of

plants reveals that plants use sunlight within the visible range and even

within this range, there is a certain capacity that plants can use and the rest

of the light incident upon them is dissipated as heat. Plants differ in the

types of chlorophyll they use in using sunlight, a fact worth noting in the selection

and design of agricultural or crop systems.

When we examine the solar to electric energy

conversion mechanisms, it is known that when light is incident on a material,

it is partially reflected, absorbed, and transmitted. Only that portion, which

is absorbed, is converted to electricity in the photovoltaic panels. These

fractions depend on the materials. There is constant research and development

to discover and formulate new materials with high absorption values. These

absorption values are typically dependent on the wavelength of the light

impressed upon them. Thus, it is possible to select combinations of electronic

materials that absorb solar radiation at wide wavelengths but allow light of

certain selected wavelength range to pass through for other potential uses.

Figure 3 shows the

spectral response of a selected set of popular materials used for solar cells.

Gallium Arsenide (GaAs), Cadmium Telluride (CdTe), amorphous Silicon (a-Si), crystalline Silicon

(c-Si), and Copper Indium Selenide (CIS) are some of the materials used in

solar panels and it may be noted that each material absorbs light (photons)

within certain specific wavelengths of the radiation and converts it into

electrical energy. The rest of the radiation is passed through the solar panel

in transparent materials. With most materials currently in use, the amount of

energy absorbed for conversion to electricity is only a small fraction of the

incoming radiation. With solar panels operating with efficiencies in the range

from 6% to 18%, it means that a large fraction of incident photonic radiation

is available past the solar panels. For example, (CIGS) cells on glass give

efficiency between 18.1% and 14%, and

flexible CIGS cells on polymer and metal foils give 16% efficiency, solar cells

with non-vacuum low cost CIGS process give 6.7% efficiency, CdTe cells on glass

give 15.4% efficiency, and flexible CdTe cells on polymer give 12.4%

efficiency. In almost all these cases of solar panels, a high proportion of the

incident radiation is available for other uses.

Indium tin oxide (ITO) can be used in nanotechnology to provide a path to

a new generation of solar cells. Solar cells made with these devices have the

potential to provide low-cost, ultra-lightweight, and flexible cells with a

wide range of applications. Because of the nanoscale dimensions of the

nanorods, quantum-size effects influence their optical properties. By tailoring

the size of the rods, they can be made to absorb light within a specific narrow

band of colors. By stacking several cells with different sized rods, a broad

range of wavelengths across the solar spectrum can be collected and converted

to energy. Moreover, the nanoscale volume of the rods leads to a significant

reduction in the amount of semiconductor material needed compared to a conventional

cell. Thus, ITO solar cells can generate electricity and also allow light at

frequencies useful for photosynthesis by plants.

Thin

film photovoltaic cells are made by depositing one or more thin layers of

photovoltaic material on a substrate and they offer lower production costs and

acceptable efficiency values. The sub-groups of thin film photovoltaic cell

include amorphous Silicon (a-Si), Cadmium Telluride (Cd-Te) and Copper Indium

Gallium Selenide (CIS or CIGS).

Polymer

solar cell (PSC) produces energy by absorbing infrared light and is not

visible. The cells are thus nearly 70 percent transparent to the human eye.

Made of photoactive plastic, the cells have been seen as highly viable

solutions for building integrated solar installations. They are fabricated in

long sheets suitable for building materials. Such Building Integrated

PhotoVoltaics (BIPV) will suit special applications in greenhouses.

By

taking conventional opaque PV materials and either making them so thin they are

translucent or “segmenting” them, “see-through” solar cells could be made with

some tradeoff between transparency and efficiency. Such a tradeoff is not

entirely negative if the transmitted energy in the light is used by the plants

and the hot water heaters. From Figure 4, we can see that transparent solar

cells fulfill these requirements admirably. These cells utilize the UV and

near-infrared (NIR) light to generate electric energy and pass the visible

light through.

MIT

researchers are making transparent solar cells (Figure 4) that could turn

everyday products such as windows and electronic devices into power

generators—without altering how they look or function today. These solar cells

absorb only infrared and ultraviolet light. Visible light passes through the

cells unimpeded. Using simple room-temperature methods, the researchers have

deposited coatings of their solar cells on various materials. They estimate

that using coated windows in a skyscraper could provide more than a quarter of

the building’s energy needs without changing its look.

Michael Grätzel produced the most

efficient Perovskite solar cells, which convert 15 percent of the energy in

sunlight into electricity. It is expected that future cells made with this type

of materials could result in efficiencies as high as 20 to 25 percent.

Perovskite solar cells can be made by spreading the pigment on a sheet of glass

or metal foil, along with a few other layers of material that facilitate the

movement of electrons through the cell. With such photovoltaic materials it is

possible to paint or spray solar cells on transparent roofs. Transparent

PV panels are available commercially as fabric and a commercial sample is shown

in Figure 5. It is also possible to stack up such fabric based solar cells over

water heaters made with the transparent fabrics.

The performance of

PV cells improves when they are cooled. Hence, by locating a hot water heater

below the transparent solar PV panels, we accomplish three things: 1) the

performance of the PV panels is improved; 2) the intensity of harmful solar

radiation reaching the plants is reduced; and 3) the heat recovered by the

water is usefully utilized in the desalination process.

The integral

passive solar water heaters (IPSWH) are typically rectangular plastic bags

holding water for heating. These

were popularly called "solar pillows" A similar model, with a simple

tray instead of bags, has also been used. The point is to minimize the thermal

energy reaching the plants in the desert environment and where possible to

utilize the collected thermal energy.

It

is known from the above description that 1) solar photovoltaic systems are not

100% efficient; 2) they do not use the solar radiation present in the entire

spectrum of sunlight; and 3) plants do not use all the sunlight they receive. Hence

technologists look for ways to develop systems that take advantage of the

mutual inefficiencies and indifference of system components to parts of the

light spectrum.

Bhatt

(US Patent 5,101,593) described a Portable greenhouse working on solar system.

He disclosed a closed chamber with windows that permit the entry of light into

a major part of the chamber where plant growth will occur while restricting

light to a minor portion thereof where germination of seeds occurs. Racks for

stacked growing trays are provided; preferably the upper part of the chamber is

used for germination. The greenhouse further includes apparatus for

accumulating solar energy in the form of electrical energy so as to drive

irrigation pumps and fans and also in the form of thermal energy to assist in

maintaining desired temperatures in the chamber.

Hajj

airport terminal uses for its roof a Birdair

provided translucent membrane material to shield the interior from the high

temperatures in the desert. That material keeps 70% of the light from entering

the interior.

SUMMARY

One

object of the invention is to develop an enclosure to allow only a controlled

portion of sunlight to impinge on the plants inside the said enclosure by

providing a transparent roof covered by successive layers of transparent solar

photovoltaic panels and transparent solar hot water heaters to produce fresh

water from sea water by desalination, which fresh water is used to feed the

plants raised in the said enclosure, and to create controlled temperature and

humidity conditions suitable to raise vegetation by supplying cooled air

produced by an air conditioning or chiller system powered by using the

electricity generated by the above mentioned solar panels and augmented by grid

power.

BRIEF

DESCRIPTION OF THE DRAWINGS

Figure

1 shows the solar radiation spectrum

Figure

2 shows the rate of photosynthesis and the amounts of sunlight in the various

wavelengths that are absorbed by the chlorophyll in plants.

Figure

3 shows Spectral Response of solar

cells.

Figure

4 shows Spectral response of

conventional and transparent PV cells

Figure

5 shows a sample of a commercial Thin Film solar PV in fabric form

Figure

6 shows how stacking takes advantage of the solar radiation spectrum and the

spectral response of photovoltaic panels.

Figure

7 shows how the wavelength spectra can be matched so that the solar radiation

can be appropriately shared and utilized by the series of devices.

Figure

8 shows a view of stacked solar PV panels and solar hot water heaters on a

transparent roof of a solar coolhouse.

Figure

9 shows a sketch of the general arrangement of the solar coolhouse.

Figure

10 shows a schematic arrangement of the solar coolhouse.

Figure

11 shows a view of the ventilation arrangement in the gable portion of the roof

of the coolhouse.

Figure

12 shows a coolhouse with the addition of a rock bed recuperator.

Figure

13 shows a solar coolhouse with hydroponics or aquaponics instead of soil based

plants grown inside the solar coolhouse.

Figure

14 shows a solar coolhouse with pisciculture cultivation.

DETAILED

DESCRIPTION

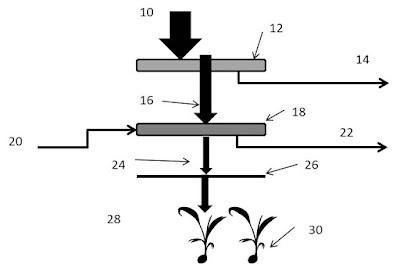

Figure

6 explains the principle of the arrangement where transparent photovoltaic (PV)

panels (12), transparent water heaters (18), and transparent roof (26) are

placed in series. With such an arrangement, solar radiation (10) passes through

the transparent PV panels (12) generating electric energy (14) and the unused

solar radiation enters the transparent water heater (18) where cold water (20) is

heated and the heated water flows (22) to a desalination system, and the

remaining solar radiation (24) finally enters the solar coolhouse through the

transparent roofing (26) to reach the plants (30) inside the coolhouse (28).

By

suitably designing and arranging the components of the system as illustrated in

Figure 7, we take advantage of the fact that transparent PV panels and

photosynthesis by plants utilize solar radiation at different wavelengths,

while the water passing through the water cools the PV panels by absorbing most

of the remaining thermal radiation. This apportionment of solar energy in

various wavelengths is further explained in Figure 5.

It is possible

to take advantage of the spectral responses and absorption and transmission

portions of light at various wavelengths, in other words, mutual inefficiencies

and indifferences, by locating the PV panels, water heaters, and plants

successively. As shown in Figure 7, by placing transparent PV cells (50) with

characteristics that allow some of the solar radiation in the visible

wavelengths shown at (40), (46), and (42) to pass through and the solar

radiation in the UV (44), part of the visible wavelength portion of light in a

particular region (46), in the Near InfraRed (NIR), and InfraRed (IR)

wavelengths (48) to be absorbed for conversion to electricity, we get the most

beneficial effect of the solar radiation. Since the transparent solar PV cells

absorb only a small portion of the solar radiation incident on them, the rest

is passed through. A greater part of such pass through solar (thermal)

radiation is absorbed in the hot water heater constructed of transparent

material such as glass or plastic (52) and the reminder passes through the transparent

roof (54) to the plants in the coolhouse. Thus the plants can get a large

portion of the light (56) and (58) in the two visible regions. Small amounts of

radiation in the UV region (60), NIR (62), and IR wavelengths (64) might also

reach the plants depending on the absorption capabilities (or efficiencies) of

the PV cells and hot water heaters. The choice of materials for solar PV cells

in the panels will be optimized to minimize the radiation reaching the plants

in the UV (60), NIR and IR (64), and the unusable (by plants) visible region (62).

As new transparent solar PV materials and cells are discovered new combinations

can be matched as closely as feasible, practicable, and economically viable

with the frequencies that are preferred by plants in order to increase the

utilization of natural solar radiation to generate electricity and to encourage

growth of plants and to minimize the need for hot water heating.

Following

the above discussed principles, we design a stacking arrangement, as shown in

Figure 8, where transparent solar PV panels (160) and solar hot water heater (162),

are stacked on top of the transparent roofing (164) of the coolhouse.

In

order to utilize most of the solar radiation effectively, we design a solar

coolhouse or a greenfarm in a desert as shown in Figure 9. The arrangement

(170) consists of a structure with opaque walls (172) on all four sides and a

transparent roof (164) on top. Solar Photovoltaic panels (160) and solar hot

water heaters (162) are stacked on top of the said roof (164). Electricity

(174) is generated using the transparent solar photovoltaic panels (160), some

of the electric power generated is utilized for local use (176) and the rest of

the energy is exported to the electric grid (178). Seawater or local brackish

water (180) is sourced and pumped (182) into the solar hot water heaters (162).

The hot water is conveyed to a desalination unit (184), where freshwater (186)

and concentrated brine (188) are separated. The resulting concentrated brine

from the desalination plant is transported to a salt production facility or suitably

disposed of outside the coolhouse. An air conditioning unit (190) powered by a

part of the electricity generated by the solar panels supplies cool fresh air

(192) to keep the environment in the coolhouse at the required temperature and

to replenish the carbon dioxide (CO2) used by the plants. The floor

(200) of the structure is prepared with soil (202) and serves as a farm or bed

for plants. Suitable plants and crops (204) are raised on the farm or soil bed.

Fresh water (186) generated by the desalination unit is sprinkled (206) on the

soil and sprayed (208) into the structure to provide controlled moisture in the

soil and humidity in the coolhouse environment suitable for plants and crops.

Figure

10 shows a schematic arrangement of the Solar Coolhouse. In this arrangement (210),

solar radiation (212) is incident on the transparent solar PV panels (214), a

part of which passes through the panels on to solar water heaters (216) where a

portion is absorbed, and the remaining radiation passes through the transparent

roof (218) and into the cool house (220). The electric power generated by the

transparent solar PV panels is taken to a junction box (222) where a portion of

the power is exported to the electric grid (224). When solar radiation is not

available, the PV panels do not generate power and power is actually imported

from the electric grid (224). Sea water or other brackish water that is locally

available is stored in a reservoir (226) from where that water is pumped (228)

to the solar hot water heaters on the roof (216). The heated sea water or

brackish water is sent to the desalination system (230). Concentrated brine from the desalination

system is collected in drains (232) and returned to salt recovery plants where

possible or otherwise disposed of. The desalination system (230) gets its

electric power requirements from the electric junction (234), which is

connected to the junction box (222). Plants (236) are grown inside the

coolhouse. The air conditioning and ventilating system (238) supplies cool air

to the coolhouse and vents the hot air and thus ensures that the environment

inside the coolhouse is maintained at the required temperature and humidity to

ensure good plant growth. A water pump (240) pumps fresh water generated by the

desalination system (230) into the coolhouse (220) to water the plants (236) by

means of sprinklers and sprayers.

The

fresh water produced by the desalination system is used to water the plants by

means of sprinklers or drip pipes and additionally, some of that water is

sprayed into the air in the coolhouse to keep the humidity at levels required

for good growth of the plants.

Where

an electric grid connection is not available, a battery back-up system is used

to store electrical energy during the sunny days for use in the nights and on

days when the sun is not shining.

Carbon

dioxide (CO2)

can be rapidly depleted at the leaf surface as plants depend on carbon dioxide

for their growth. A slight wind is necessary to replenish carbon dioxide (CO2) near

the plant surface (236). In a fully

enclosed coolhouse, fans will be used to bring outside air to replenish carbon

dioxide (CO2).

Hence, by providing ventilating blowers in the gable portion of the coolhouse,

the twin purposes of replenishing carbon dioxide (CO2) and

venting the hot air are accomplished.

Figure

11 presents a view to show the ventilation arrangement. The solar radiation (240)

incident on the structure consisting of transparent solar PV panels and hot

water heater panels covering the transparent roof (242) will be likely to cause

the air in the solar coolhouse (244) to heat. Some external heat will penetrate

the structure (246) through the parts of the roof (248) where no solar panels

might be located and the walls, and infiltration of outside air through the

entry doorways. Such hot air will accumulate in the gable portion and increases

the load on the air conditioning system if it is not vented. Ventilating

blowers or fans (250) are optionally installed in the gable portion of the

structure. By turning these fans on, air that is hot and deficient in carbon

dioxide (CO2)

can be ventilated and the temperature inside the structure can be kept at the

desired level without placing undue burden on the air conditioning system.

In

certain deserts, while the day time presents scorching temperatures, the night

time temperatures dip too far and it becomes very cold for the plants. Figure

12 shows an optional chamber (260) with a bed of rocks (262) added to the

coolhouse. This bed of rocks works as a

recuperator. During the day, a fan (264) draws the prevailing hot air from the

outside through the bed of rocks. The resulting heat exchange heats the rock

bed and cools the incoming air. Such cooled air is admitted into the coolhouse.

During the night time, when cold air from the outside air is pulled through the

hot rock bed, the air warms up before it enters the coolhouse. The rock bed

gives up its heat and cools itself. The air entering the coolhouse in the night

time presents no harm to the plants in the coolhouse as it is warmer than the

outside. Such a recuperative cold store will further save energy. With such

controlled recuperative arrangements, the environment in the coolhouse is

maintained within limits that allow plants to thrive while lowering energy

expenditures on air conditioning. In the event the desert nights present severe

cold temperatures, the air conditioning system can be operated in reverse as a

heat pump to maintain the required conditions in the coolhouse to protect the

plants from cold freeze.

In

the solar coolhouse arrangement described so far, transparent solar PV panels

and solar hot water panels are placed on the side where solar insolation is

predominant. The numbers, sizes, capacities, and placement coverage of the

solar PV panels and solar hot water panels are determined at the time of design

by the actual requirements of hot water, solar PV electric energy, and the

amount of direct sunlight required by the plants inside the Coolhouse.

In

the Solar Coolhouse arrangement described above, the floor is a bed of soil

where plants are grown. In deserts the quality of soil is poor and to

compensate for that we go for hydroponic cultivation. An alternative arrangement consists of

providing hydroponics to grow crops in the Solar Coolhouse as shown in Figure

13. In the solar coolhouse (170), instead of soil on the floor (200), water

containers (270) are located with plants (272) growing in them. Fresh water

from the storage reservoir (184) is drawn via pipes (186) by the water pump (274)

and pumped via pipes to the water containers (276). Water leaves the containers

via outlet pipes (278) to return to the fresh water storage unit via pipes (280)

and to the water sprayers (208) in the cool house to ensure proper humidity in

the solar coolhouse. Appropriate mineral nutrient solutions are added to the

water flowing in the containers.

Appropriate mineral nutrient solutions and fish food are added to the

water flowing in the containers. While a variety of vegetables, flowers, herbs, and plants

can be grown in solar coolhouses equipped with hydroponics, traditional

facilities have successfully grown Artichokes, Asparagus, Beans, Beets,

Broccoli, Brussel Sprouts, Cabbages, Carrots, Cauliflowers, Celery, Cucumber,

Eggplants, Leeks, Lettuce, Onions, Parsnips, Peas, Potatoes, Radishes, Rhubarb,

Squash, Tomatoes, and Yams.

Yet

another alternative arrangement consists of providing Aquaculture or Pisciculture

where fish are raised in the water-filled troughs with plants being grown in

the same water-filled troughs as shown in Figure 14. Water-filled containers (290)

are used to grow plants (292) and also to raise fish (294). Fresh water from

the storage reservoir (184) is drawn via pipes (186) by the water pump (274)

and pumped via pipes (276) to the water containers (290). Water leaves the

containers via outlet pipes (278) to return to the fresh water storage unit via

pipes (280) and to the water sprayers (208) in the cool house to ensure proper

humidity in the solar coolhouse. Appropriate feed materials are added to the

water in the tanks for the fish to flourish and for the vegetable plants to

thrive. Besides vegetables,

a variety of fish species including salmon, catfish, tilapia, cod

Katla, Rohu, Mrigal, and exotic or common carps can be raised in aquaculture or

pisciculture in a solar coolhouse.

Several

alternative arrangements and configurations are possible within the scope of

the description and some typical alternatives are described below.

In

some deserts, the night time temperatures will be very low. Hence, water

storage units and heat exchangers can be used to improve the performance of the

solar coolhouse system. By passing seawater through the roof top heaters in the

night time, water can be cooled to low temperatures and saved in water storage

tanks. During the daytime, the stored cold water can be passed through the roof

top heaters to heat the seawater. Auxiliary water to air heat exchangers can be

used to use the stored cold water to cool the air being drawn into the

coolhouse. Such a subsystem will reduce the load on the air conditioner and

during certain times of the day and season, it may eliminate the use of the air

conditioners completely. Likewise, the same water to air heat exchangers can

provide temperate air into the solar coolhouse. This heat storage in water will

save energy used in providing the proper environment in the coolhouse.

With

the electrical energy generated or imported from the electric grid, it is

possible to extend the hours when the plants get light by adding electric grow

lamps. Such an arrangement will allow for rapid and robust growth and crop

yields.

By

incorporating the solar humidification-dehumidification (HDH) process

additionally, seawater or local brackish water can be sprayed as a mist and the

resulting fresh water can be collected and used to water the plants in the

coolhouse.

Seasonal

and daily variations in temperature and solar radiation would vary the need for

electrical energy by the coolhouse environment conditioner. Connection to

electrical grid would help the system and economics. Where such a connection to

the electrical grid is not available or economical battery storage will help.

Desalination

of seawater or locally available hard water can be done by raising steam in

auxiliary concentrated solar heaters.

In

cold deserts, such as Ladakh region in India, where water and good soil for

cultivation are scarce, solar heating can be used to melt the ice and snow

recovered in the winter and hydronic and pisciculture can be utilized with

solar coolhouses to raise plants and fish. Such ice can also be used to cold

pack fruits and vegetables and export them to other regions.

A

computer operated environmental control subsystem will assist in the proper

operation of the solar coolhouse.

Following

developments in solar photovoltaics on clothing, transparent photovoltaic thin

films can be glued to a semi-transparent roof of the coolhouse structure in the

desert.

The

side of the solar coolhouse that has no exposure to the sun will have a roof

made of opaque material and will carry no solar photovoltaic panels. It may be

equipped with wind turbine ventilators to aid in controlled ventilation of the

hot air from the gable portion of the roof of the coolhouse.

Where

seawater is not available but fresh water is available, desalination process will

be eliminated and such fresh water in place of seawater in the water heaters on

the roof of a coolhouse.

It

is also possible to utilize designs which do not use water heaters at all while

sacrificing some advantages.

It

is possible that by controlling the rate of amount of flow of seawater or other

medium in the heaters on the roof of the coolhouse during bright sunny to

cloudy days to augment the amount of light energy reaching the plants to

optimize their growth and development.

It

is possible to use an intermediate clear fluid such as polyethylene glycol in

the solar heaters on the roof and to transfer that heat from that fluid to the

seawater prior to its entry to the desalination system. This arrangement will

have the advantage of using clean intermediate fluid rather than the seawater

which may be dirty and turbid.

Since

the plants in the structure do not depend on the external atmosphere, plants

can be grown throughout the year. The economics can be highly favorable as the

roof structure is doubling as the energy generator and as a shield from the hot

sun in a desert for the crops inside.

Where

necessary skylights can be added to the roof to allow additional sunlight to

enter and shine on the vegetation in the coolhouse. In such a case, it is

possible that only certain spots receive sunlight and not all the plants

receive light uniformly. In order to rectify such situations, Fresnel lenses

may be added to the skylights so that the sunlight is distributed to all the

plants in the structure.

Where

solar thermal radiation is severe and the plants do not need the sunshine for

certain periods of time, black fabric shields or curtains can be pulled on the

inside of the coolhouse roof to reflect the sunlight away from inside thus

saving on the energy required for air conditioning. Likewise in certain deserts

where poor cloud cover exposes the environment to the blue night sky and cause

very low temperatures to prevail. In such situations, black fabric shields or

curtains can be pulled inside to protect the plants from freezing inside the

solar coolhouse.

It

may be noted that the space in the coolhouse can be used as a warehouses for

grains and other food products, instead of or in addition to raising crops. With

such uses, solar coolhouses can find home in locations with incessant or

intermittent rainfall.

Although

we described coolhouses here, their sizes can be extended to large values to

build solar cool farms or greenfarms on the one hand and the concept can be

applied to cool boxes on the other so that people can grow plants in their

kitchen windows.

We

described the concept as applicable to deserts but it does not preclude the use

of solar coolhouses on the seas. Especially pisciculture may be advantageous in

offshore locations.

Solar

coolhouses can be located on top of multistory homes for penthouse gardens as they

give a cool outdoor garden atmosphere for plant growth as well as to yield

vegetables, fruits, and flowers in otherwise harsh and unwelcoming environments.

Just

as people have gardens around their houses, they can have a solar coolhouse

garden on their yard and enjoy the coolness as well as the greenery and fresh

fragrances coming from the horticulture.

As

new developments in PV technology give rise to transparent PV cells with high

efficiencies, there will not be sufficient solar radiation and light left to

heat the water as well as to provide sufficient sunlight to the plants. In such

cases, auxiliary solar water heaters and solar tubes for light may be utilized.

Large solar coolhouses can be turned into solar coolfarms by

using translucent fabric for their roofs currently used for airports in deserts

along with transparent solar photovoltaic panels and solar water heaters described

here.

Benefits:

Solar coolhouses turn desert-like areas into productive

and high value farming enterprises. They harness the sun’s energy and utilize

most of it in the process. Besides agricultural products like vegetables,

fruits, and flowers, they can also yield electrical energy, fresh water, and

cool environment. By covering vast areas of the desert, they can prevent

further soil loss from the deserts. They utilize seawater and local brackish

water in the process and turn it into fresh water for the crops and any excess

is provided to the local communities. They turn urban penthouses into roof

gardens with similar products as well as reduce heat load on the surroundings.

Figures:

Figure 1 shows the solar radiation spectrum.

Figure 2 shows the rate of photosynthesis and the amounts of sunlight in the various wavelengths that are absorbed by the chlorophyll in plants.

Figure 3 shows Spectral Response of solar cells.

Figure 4 shows Spectral response of conventional and transparent PV cells.

Figure 5 shows a sample of a commercial Thin Film solar PV in fabric form. (reference available on request.)

Figure 6 shows how stacking takes advantage of the solar radiation spectrum and the spectral response of photovoltaic panels.

Figure 7 shows how the wavelength spectra can be matched so that the solar radiation can be appropriately shared and utilized by the series of devices.

Figure 8 shows a view of stacked solar PV panels and solar hot water heaters on a transparent roof of a solar coolhouse.

Figure 9 shows a sketch of the general arrangement of the solar coolhouse.

Figure 10 shows a schematic arrangement of the solar coolhouse.

Figure 11 shows a view of the ventilation arrangement in the gable portion of the roof of the coolhouse.

Figure 12 shows a coolhouse with the addition of a rock bed recuperator.

Figure 13 shows a solar coolhouse with hydroponics or aquaponics instead of soil based plants grown inside the solar coolhouse.

Figure 14 shows a solar coolhouse with pisciculture cultivation.

References and Prior Patents:

Available upon request.